OMMS-class systems

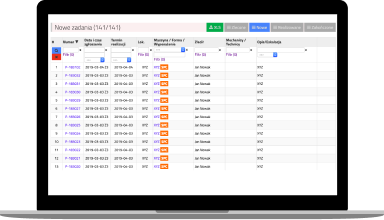

OMMS (Online Maintenance Management System) is a group of projects and a series of implementations of systems supporting processes in maintenance departments.

They handle among the others: inventory of machines and equipment, registration and processing of events, planning preventive actions and supervision over spare parts warehouses.

All you need in maintenance

OMMS is a comprehensive solution for the maintenance department.

The system has modules responsible for the recording of machines and devices, prevention planning, spare parts warehouse, gathering documentation or verification of crew skills.

Real-time analysis

The maintenance department to determine its effectiveness often uses indicators such as MTTR (Mean Time To Repair), MTBF (Mean Time Between Failures) or OEE (Overall Equipment Efficiency).

OMMS includes a module for calculating these indicators in real time in various scopes: for the entire plant, for location, for a group of machines, for mechanics and many others.