Electronic KANBAN

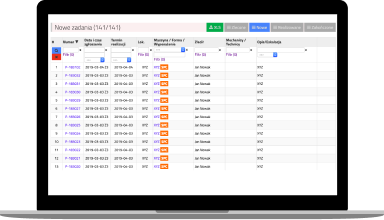

Forget about paper kanban cards. Forget also about delays, incorrect deliveries and disputes between logistics and production representatives about who's guilty.

The eKANBAN application is a simple solution that allows to reduce more a mean materials transportation time by a half and achieve 100% order-delivery compliance.

Simple to use

eKANBAN is an extremely easy to use web application that can be used by people who have no contact with a computer on a daily basis.

Thanks to this, it takes around around 10 seconds to place an order while a delivery service takes 2 times for 5 seconds.

In addition, eKANBAN does not require installation - all you need is network access and a web browser.

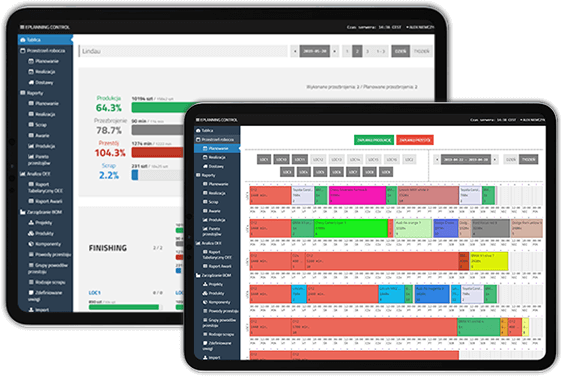

Flexible and extensible

On the other hand, eKANBAN is a very advanced and flexible system that allows its administrators to freely configure and map a production plant environment.

In addition, eKANBAN easily integrates with external systems, e.g. SAP ERP, RFID or barcode identification systems.

Your data is 100% safe. According to

privacy policy we do not share your information with external parties.